如果您使用的是立体光固化 (SLA) 3D 打印机,那么了解如何后固化您的树脂 3D 打印件十分重要。后固化过程能够尽可能提高部件强度并增强部件稳定性。但每种树脂在后固化后的性能略有差异,需要采用不同的时间和温度才能达到材料的最佳性能。

为什么要固化树脂打印件?

每种 Formlabs 树脂均采用先进的光敏聚合物化学反应进行配制。Formlabs 立体光固化成型 (SLA) 3D 打印机使用 405 nm 激光固化液态树脂,生产出高精度的固体部件。打印完成后,SLA 部件会在构建平台上保持“原始状态”。这意味着,虽然部件已达到最终形态,但聚合尚未彻底完成,部件未达到其最佳机械性能。如需充分解锁 SLA 3D 打印件的材料性能,通过光照和加热进行后固化是关键的最后一步。而对于生物相容性材料,后固化处理更达到监管机构所规定安全标准的关键所在。

使用功能性树脂或特殊树脂时,实现最佳性能尤为重要。Formlabs 提供两种后固化解决方案,分别为 Form Cure 和 Form Cure L,旨在快速一致地对使用 Formlabs 树脂打印的部件进行后固化。Form Cure 和 Form Cure L 是我们的工程师专为 Formlabs 树脂而研发的后固化设备,并使用与 Formlabs SLA 3D 打印机相同的 405nm 激光。在反射室内自动旋转并加热部件,以确保均匀一致的后固化效果。

后固化原理简介

SLA 3D 打印使用的任何树脂都可视为高度交联的大分子,或是聚合物链(单体和低聚物)组成的连续网络。在这种大分子中,仍然存在一些反应基团,在光照和加热条件下,才可以进一步交联形成聚合物网络。

随着交联结构逐渐增多,拉伸模量和拉伸强度等材料性能将明显提升。后固化的目的是尽可能多地联接这些尚未反应的基团,在最大程度上提高部件的材料性能。

达到最优材料性能后,如果仍继续进行后固化,可能会导致某些树脂变脆或发生翘曲。因此,针对每种树脂和部件几何形状,设计特有的后固化方案,并且必须设置特定的时间和温度,以免过度固化。

要实现最佳后固化效果,首先要进行适当加热。高温会增加聚合物网络中的能量,从而提高内部反应基团的流动性。因此,反应基团有更大的概率互相结合,从而实现进一步连接。Formlabs 的后固化设备 Form Cure 和 Form Cure L 均使用加热器帮助固化室快速达到所需温度,然后在整个后固化过程中保持该温度。

达到所需温度后,随即启用光线照射部件。激光中的光子会激活剩余的光引发剂,使其附近的反应基团产生粘连并完成交联过程。每形成一处新的交联都会使聚合物网络更加牢固,材料性能也相应得到改善。

随着树脂中形成更多的交联,聚合物网络的致密性略微提升,导致整个部件出现轻微收缩。这对于使用树脂 3D 打印机生产的部件,属于正常情况。Formlabs 的免费打印文件准备软件 PreForm 可以自动补偿这种收缩,从而确保后固化部件在尺寸上与原始 CAD 设计一致。

固化树脂 3D 打印件耗时如何?

理想的后固化设置会在最佳时间内实现您所需要的性能。对于 Formlabs 通用树脂,您可以使用 Form Cure V2 进行一分钟的快速固化。在需要强度、固化和耐高温的应用中,Formlabs 工程树脂的后固化时间可长达 120 分钟,具体取决于所使用的后固化硬件。

Formlabs 通过在内部开展后固化研究,确定了每种 Formlabs 树脂的最优设置。我们的材料科学家使用 ASTM 方法测试了每种材料在不同温度下的各项机械性能。

有关 Form Cure V2、Form Cure V1、Form Cure L V2 或 Form Cure L V1 的最新后固化设置建议,请访问我们的网站。您还可在网站上下载材料数据表,其中包含执行建议的后固化操作后部件的具体机械性能。

“Form Cure L 的最大优势当属显著降低的翘曲变形和更卓越的尺寸精度,大幅提升配合组件的装配效率。”Radio Flyer 的产品设计工程师 Agostino Lobello 表示。在此处了解详情。

生物相容性材料和后固化

随着越来越多的牙科和医疗专业人员将 3D 打印纳入工作流程,3D 打印公司必须确保有效管控整个流程,以便始终如一地为最终用户制造具有生物相容性和安全性的高性能部件。要满足生物相容性要求,就要严格遵循预批准的工艺,打印流程的后固化步骤同样如此。

Formlabs 技术已在 FDA 批准的工作流程中得到验证,这意味着在使用面向生物相容性应用的各类树脂时,必须遵循特定的打印、清洗和固化步骤,不得有任何偏差,这样才能将最终部件视为生物相容性设备。

Form Cure 和 Form Cure L 是这些工作流程中必不可少的一部分。我们的后固化时间设置已通过仔细的测试和全面的监管程序,能够确保每个用于生物相容性应用的打印部件均达到最佳机械性能,并且始终具备足够的使用安全性。

请参阅每种材料的制造指南,查找针对每种材料的具体后固化建议。

方法

理想的后固化设置会在最佳时间内实现您所需要的性能。Formlabs 通过在内部开展后固化研究,确定了每种 Formlabs 树脂的最优设置。我们的材料科学家使用 ASTM 方法测试了每种材料在不同温度下的各项机械性能。

为介绍后固化对机械性能的影响,本示例将着眼于拉伸模量的变化,即在 Form Cure 或 Form Cure L 中,每种树脂部件的刚度随时间的变化。拉伸模量较高的部件在应力下的抗变形能力更强。弹性模量与部件内光聚合物链的交联程度密切相关,因此,Formlabs 使用模量来表示后固化的整体完成度。

模型的“原始”形状是在打印过程中通过固化树脂形成的,但其中可能有一些聚合物连接仍未完成。将剩余聚合物按比例交联,可提高部件的强度、刚度和耐高温性。后固化也会导致部件轻微收缩。在完成标准后固化流程后,Formlabs 测量了部件的精度和机械性能,并已调整材料设置,将相应的收缩情况考虑在内。部分树脂无需进行后固化,但如果进行后固化,其机械性能会发生变化。

示例:Rigid 4000 Resin 的建议后固化设置

本示例中,Rigid 4000 Resin 在后固化过程的前 15 分钟,弹性模量迅速增加到 116%。15 分钟后,未观察到进一步的提升。

Rigid 4000 Resin 是一款玻璃填充复合材料,用于打印高刚度、高强度且在负载下不易变形的部件。后固化能够使玻璃微粒周围的聚合物基体进一步交联,并牢牢固定在适当位置,从而直接提高材料的强度和刚度。Rigid 4000 Resin 的后固化效果受温度影响较大。温度较高时,弹性模量能够在短时间内大幅提升。建议后固化 15 分钟即可,如果继续进行后固化,虽然不会影响性能,但会导致部件表面泛黄。对于 Rigid 4000 Resin 的大多数应用,建议在 Form Cure 中在 80°C 的温度下后固化 15 分钟。

后固化故障排查

部件在后固化期间最常出现的问题是欠固化和翘曲。如果部件的硬度和刚度似乎低于预期,则可能是因为后固化不充分。如果部件特别厚或特别大,就可能发生欠固化,因为较大的部件需要加热更长的时间。仅靠光照无法充分后固化部件内部,因此 Form Cure 和 Form Cure L 会同时采用加热和光照对部件进行后固化。如果部件的几何尺寸比 Formlabs 的测试件大得多或厚得多,则可能需要更长的后固化时间或更高的温度,才能使部件内部充分后固化。

如果部件特别薄并且各侧面无法均匀接受光线照射,则在后固化期间可能会发生翘曲。在后固化期间,Form Cure 和 Form Cure L 会在转台上旋转部件,使其接受来自各个方向的光线照射,包括来自转盘下方的光线,从而防止出现翘曲变形。

相比原始部件,经过后固化的部件也会更脆。通常情况下,随着模量的增加,伸长率会降低;因此,过度固化的部件可能因会变脆而无法满足要求。

后固化硬件

后固化有很多方法,包括简单的光固化(自然光、紫外线美甲灯、紫外线固化站、DIY 紫外线固化箱等)以及同时使用光和热等。热处理能够加速这一过程并形成更完整的键合,从而提高材料性能,这是仅通过光固化无法实现的。

2017 年初,Formlabs 发布了首款专为 Formlabs 树脂打造的后固化硬件产品 Form Cure V1。自 Form Cure 和大幅面 Form Cure L 升级以来,后固化时间已缩短多达 6 倍。

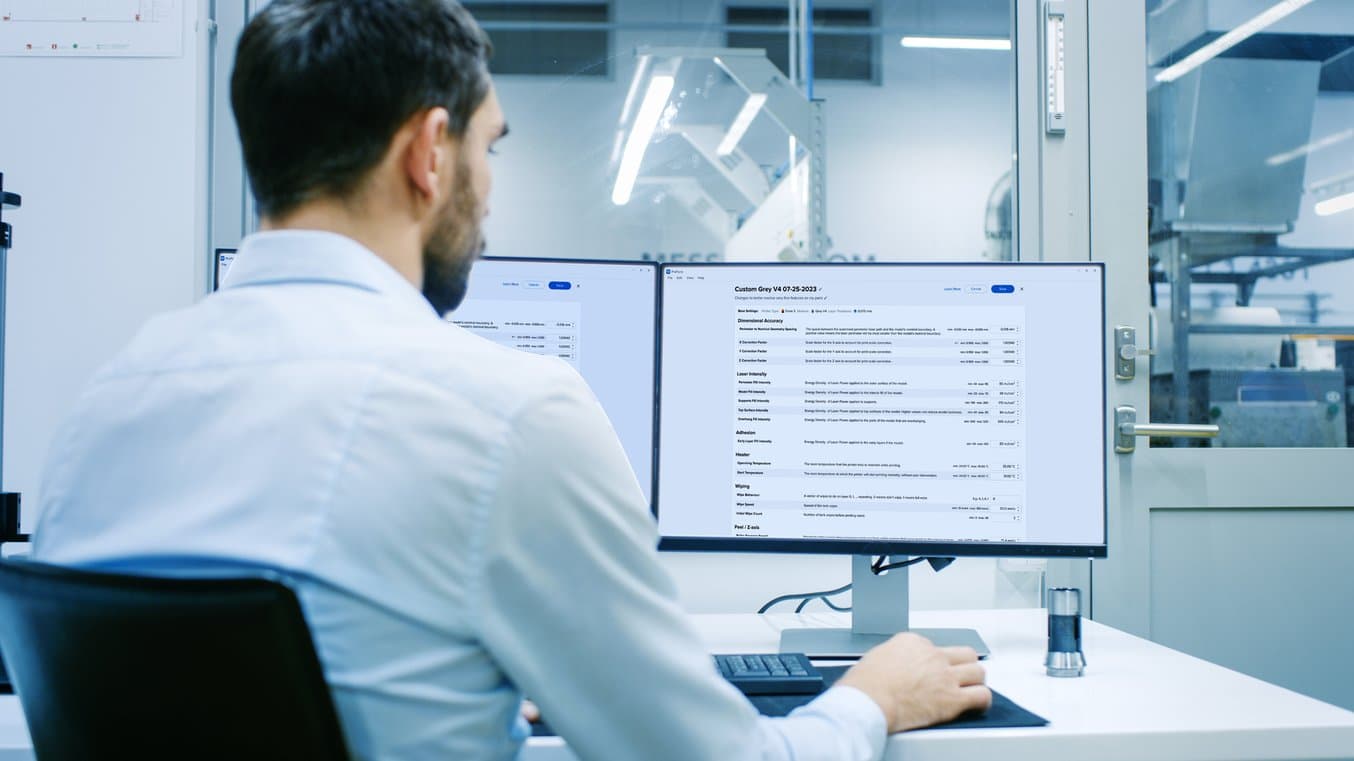

Formlabs 提供两种后固化解决方案,分别为适用于桌面级 SLA 3D 打印机的 Form Cure 和适用于大幅面专业级 SLA 3D 打印机的 Form Cure L,旨在快速一致地对使用 Formlabs 树脂打印的部件进行后固化。Form Cure 和 Form Cure L 针对每种 Formlabs 树脂预设了合适的后固化时间和温度设置,从而消除后固化过程的不精确性,并且使用户能够使用符合生物相容性类别或设备要求的生物相容性树脂实现安全打印。在新树脂发布时,用户只需更新 Form Cure 中的固件,即可获取实现最佳材料性能所需的特定时间和温度设置。

Form Cure 使用 405nm 光源并已经过全面的内部测试,能够以最有效的方式帮助 Formlabs 打印机打印的部件达到最佳拉伸模量和拉伸强度。相比之下,在相同的时间和温度下,如果使用 365nm 光源,打印样品部件的拉伸模量仅为使用 405nm 光源时的 67%。使用不同波长光源后固化的部件性能存在显著差异,在后固化时间较短时,这种差异尤为明显。

作为一款大尺寸设备,Form Cure L 不仅适用于固化大型部件,还可对许多小型部件进行高效后固化,实现批量生产。一个牙科实验室可能需要配备五台 Form 4B 3D 打印机,但只需一台 Form Cure L 即可一次性固化所有部件,从而节省时间、空间与人力。

开始固化 SLA 树脂 3D 打印件

Formlabs 提供大体积和小体积两种固化选项轻松完善 SLA 3D 打印工作流程。Form Cure 和 Form Cure L 已经过全面的内部和外部验证测试,能够轻松扩大 SLA 生产规模。

Formlabs 材料预先设定设置,可轻松在 Form Cure 和 Form Cure L 中实现部件的后固化。此外,还可保存新的预设值。要开始轻松固化部件,可购买 Form Cure;若需处理大尺寸部件或高产量应用,则可选择 Form Cure L。有关树脂固化时间和温度的最新综合列表,请查看我们的支持网站资源:

探索 Form Cure 和 Form Cure L,或联系销售以了解更多信息。