Rebound Resin:生产级弹性 3D 打印材料

Rebound Resin 的抗撕裂强度、拉伸强度与伸长率分别是市场上其他生产级弹性材料的 5 倍、3 倍和 2 倍,适用于 3D 打印复原性弹性部件。

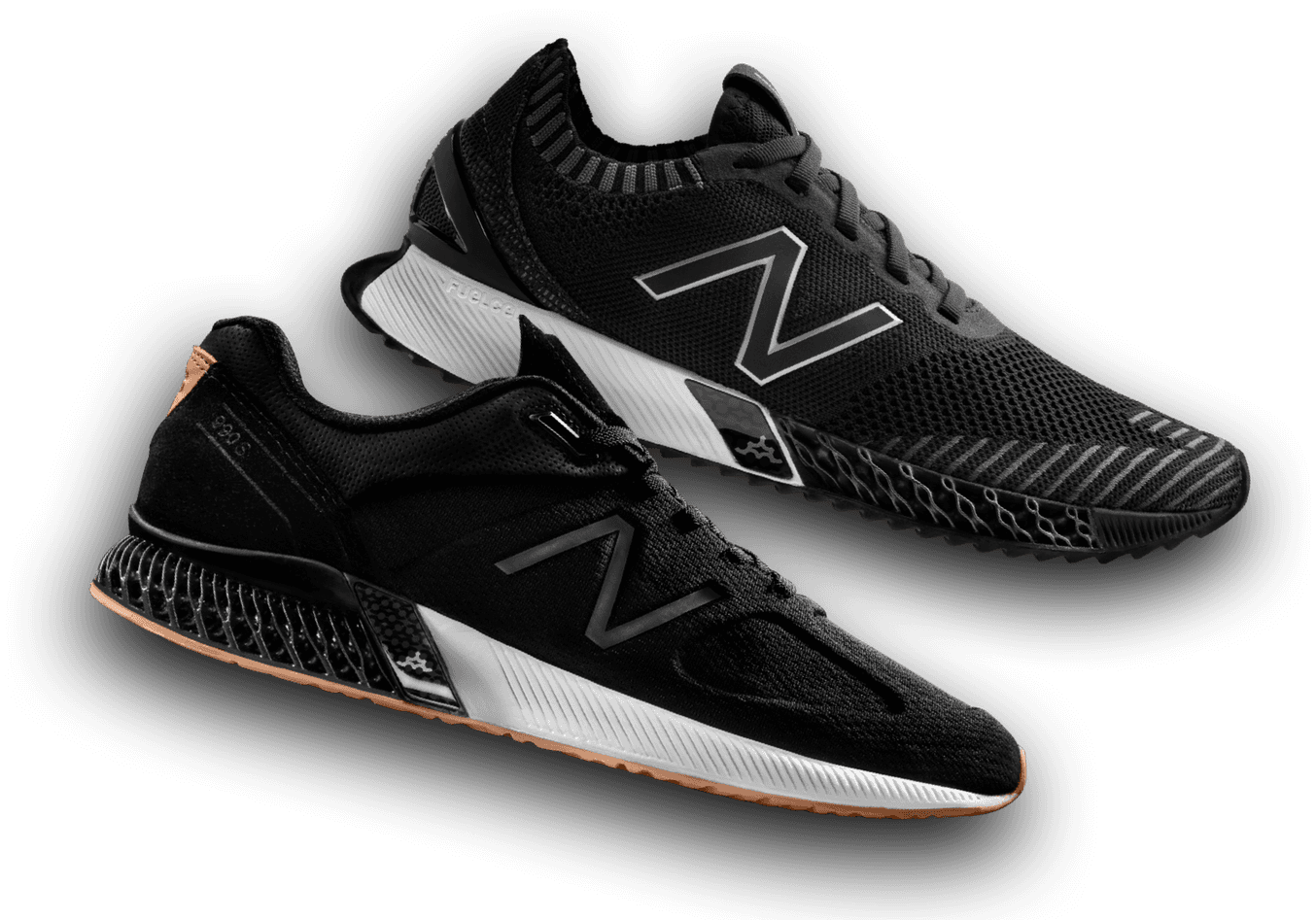

Formlabs 与 New Balance 独家合作开发鞋类产品,这种尖端材料经过两年的定制开发和严格测试,您会从中获益匪浅。

Rebound Resin 有最小订购量,其打印和后处理要求与其他 SLA 树脂不同。与 Formlabs 合作评估和实施该材料的生产。

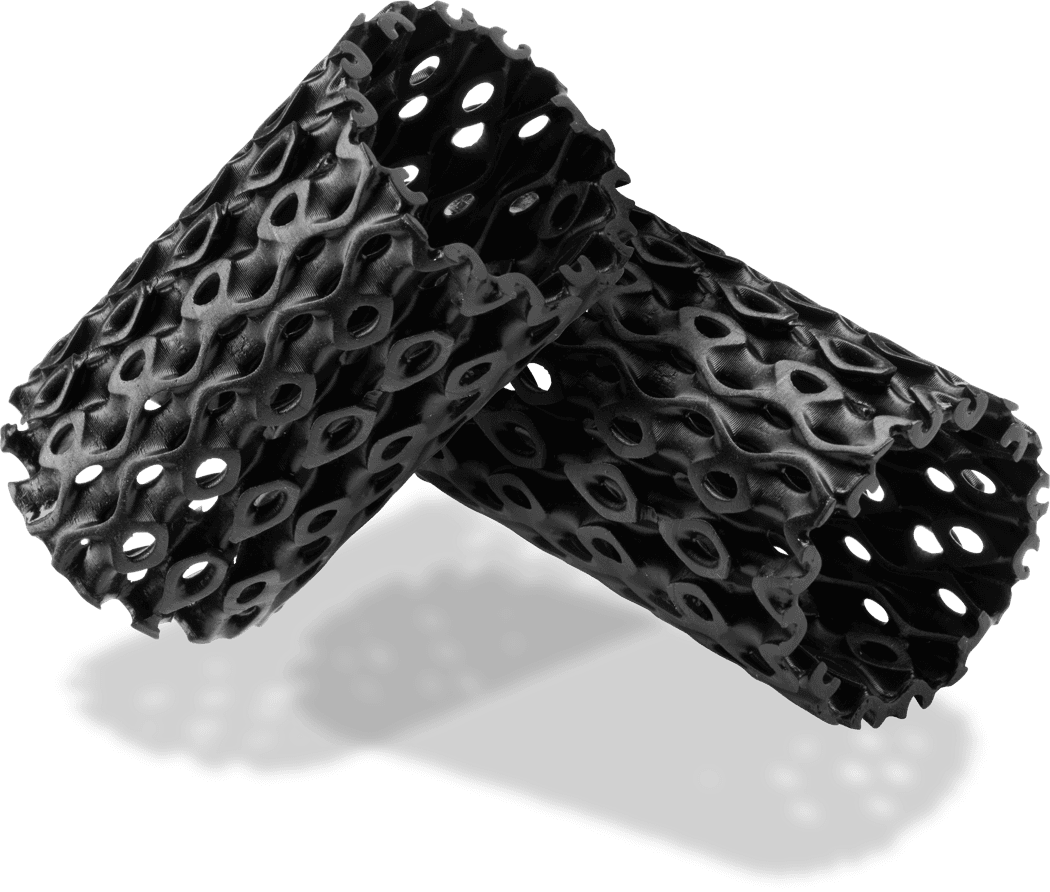

可复原的弹性结构。

Rebound Resin 具有高延伸率,因此十分适合制造有触感要求的弹性部件,例如把手和手柄等。

300%

压力下性能完好。

Rebound Resin 的强度足以承受持续的压力或张力,非常适合制造经久耐用的复杂垫圈和密封件。

110kN/m

22MPa

数英里的实际测试

目前用 Rebound Resin 制作的 New Balance 运动鞋已经上市,畅销全球。

Rebound Resin 适合各种自然环境,在各种天气条件下均经久耐用,而且其各项性能均优于传统材料。

57%

使用 Rebound Resin

与其他 Formlabs 产品相比,Rebound Resin 使用起来更加复杂,并且需要执行额外的步骤才能成功生产。

该材料通过与 Formlabs 的合作独家提供,

需要满足最小货量承诺才能开始使用。

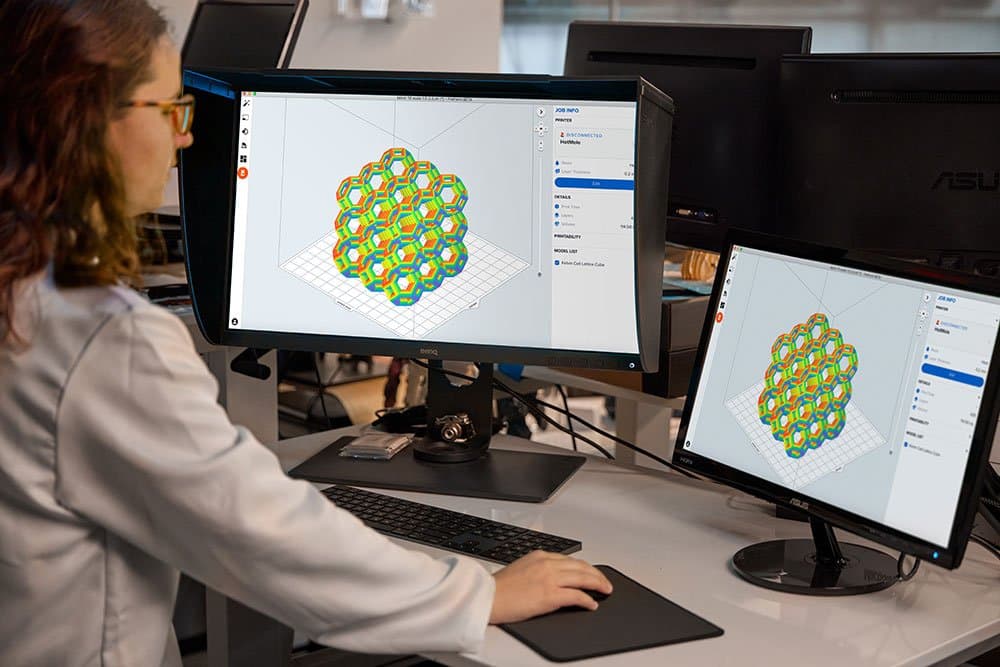

1. 设计

Rebound Resin 需要在特定的限制条件下进行设计,以便成功打印。从细节做起,遵循使用指南并进行尝试。

2. 准备树脂

与 Formlabs 合作,确保该材料有合适的打印环境。选择与您的生产量相匹配的树脂交付方式。

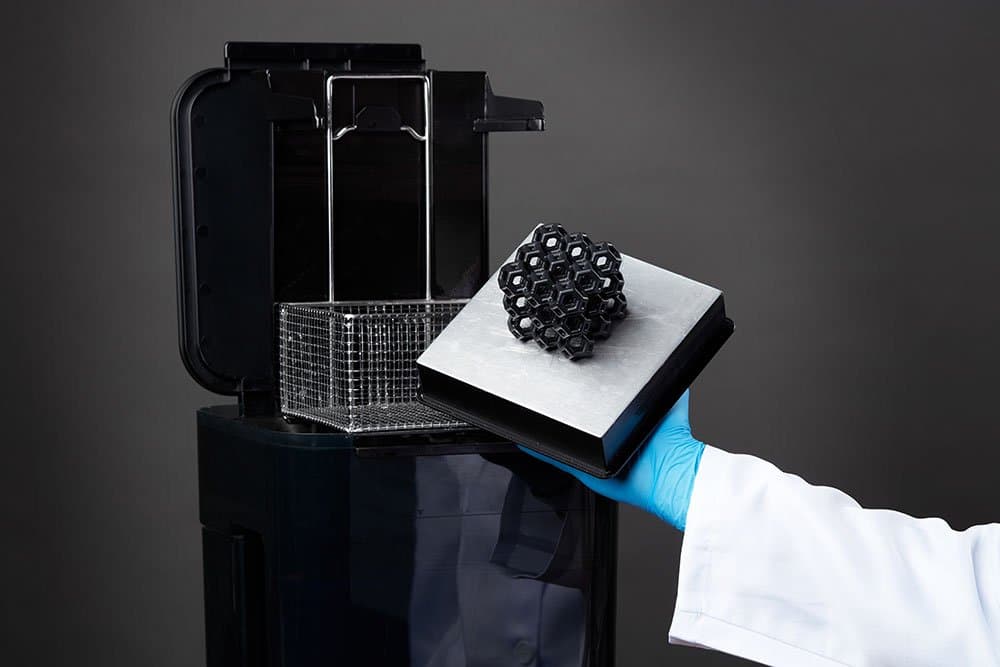

3. 打印和后处理

遵循 Rebound Resin 特定建议,冲洗并后固化部件。联系 Formlabs 了解如何设置 Rebound Resin 打印站。

让 3D 打印成为您的秘密武器

Formlabs 可以帮助您的团队探索和实施使用增材制造的新方法,以加强现有业务、推出新举措,并探索新的定制材料,满足您独特的项目需求。